Ever wondered why your pickup truck feels different to steer than your compact car? The answer might lie in what's under the hood – specifically, the steering system. While many modern vehicles use rack and pinion steering, a large number of trucks (and some SUVs) still rely on a seemingly older technology: recirculating ball steering.

Let's be honest, sometimes wrestling the wheel of a big truck can feel like a workout. There's a certain vagueness, a lack of immediate feedback that can be frustrating, especially if you're used to the precise and responsive steering of a smaller car. It makes you wonder why manufacturers haven't universally switched to something more modern.

This blog post will delve into the world of recirculating ball steering, explaining what it is, how it works, and most importantly, why it remains a popular choice for trucks and other heavy-duty vehicles. We'll explore its advantages and disadvantages, and shed light on why engineers haven't consigned this technology to the history books just yet.

Essentially, recirculating ball steering provides the muscle needed for larger vehicles, particularly when hauling heavy loads or navigating rough terrain. While it may not offer the same sporty feel as rack and pinion, its durability, strength, and ability to handle significant weight make it a crucial component in many trucks. We will cover what recirculating ball steering is, it's history, and how it works. We will also cover why it's still relevant in the trucking industry today.

The Day I Learned About Steering Systems

I remember the first time I really thought about steering systems. I was helping my dad work on his old Ford pickup truck. He was complaining about the "play" in the steering wheel, how it felt loose and unresponsive. At the time, I just nodded along, vaguely understanding that something was wrong. He started explaining the difference between rack and pinion and recirculating ball steering, and I was instantly hooked. He showed me the beefy components of the recirculating ball system on his truck, and explained how it was designed to handle the heavy loads he often hauled. It was a hands-on lesson in engineering and practicality.

What really struck me was the sheer robustness of the system. The recirculating ball mechanism seemed almost agricultural in its simplicity, yet incredibly effective. He explained how the balls within the system reduced friction, allowing for easier turning despite the weight and forces involved. He also highlighted the downsides, the lack of precise feedback and the tendency for wear over time, leading to that dreaded "play" in the steering. That day, I gained a newfound appreciation for the engineering choices that go into designing a vehicle, and the trade-offs that are often necessary.

Recirculating ball steering is designed to handle the greater weight and stress of larger vehicles. These systems are stronger and more durable than rack and pinion steering and allow for higher steering ratios and greater mechanical advantage. This reduces the effort needed to turn the steering wheel, which is especially important when the truck is heavily loaded or when navigating challenging terrain.

What Exactly Is Recirculating Ball Steering?

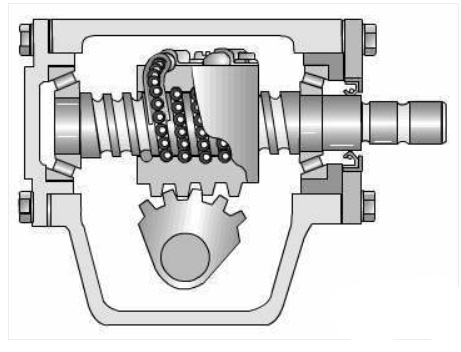

At its core, recirculating ball steering is a system that uses ball bearings to reduce friction between the steering gear and the steering box. Unlike rack and pinion, which directly connects the steering wheel to the wheels via a toothed rack, recirculating ball systems use a worm gear and a sector shaft. When you turn the steering wheel, the worm gear rotates, moving a block containing ball bearings. These balls circulate through the gear, reducing friction and allowing for smoother movement. The movement of the ball nut then rotates the sector shaft, which is connected to the steering linkage, ultimately turning the wheels.

The key advantage of this system is its ability to handle high loads and stresses. The recirculating balls distribute the force evenly, preventing excessive wear on the gear teeth. This makes it ideal for trucks and SUVs that often carry heavy loads or operate in demanding conditions. While it may not offer the same level of precision and feedback as rack and pinion, its robustness and durability make it a valuable choice for heavy-duty applications. This is why you'll still find it under the hoods of many trucks today.

Another important factor is the ease of maintenance. While any steering system requires occasional attention, recirculating ball systems are generally considered to be more forgiving and easier to repair than rack and pinion systems, particularly in older vehicles. This can be a significant advantage for truck owners who rely on their vehicles for work and need a system that can withstand the rigors of daily use.

A Brief History and Some Myths

Recirculating ball steering has been around for quite some time, dating back to the early 20th century. It emerged as a solution to the challenges of steering heavier vehicles with larger tires, which required more force to turn. As vehicle weights and sizes increased, the need for a more robust and reliable steering system became apparent. Recirculating ball steering offered a solution that could handle these demands, quickly becoming a standard in trucks and other heavy-duty vehicles.

One common myth is that recirculating ball steering is simply outdated and inferior to rack and pinion. While rack and pinion systems offer superior feel and precision, they aren't necessarily the best choice for every application. Recirculating ball steering remains a viable option for trucks and SUVs because of its strength, durability, and ability to handle heavy loads. It's a testament to its effectiveness that it's still in use today, despite the availability of newer technologies.

Another misconception is that all recirculating ball systems are the same. In reality, there are variations in design and implementation, each with its own strengths and weaknesses. Some systems use hydraulic assistance to further reduce steering effort, while others rely on purely mechanical linkages. Understanding these differences can help you choose the right steering system for your specific needs and driving style. Ultimately, the best steering system is the one that provides the right balance of performance, reliability, and cost.

The Hidden Secret: Mechanical Advantage

The "hidden secret" of recirculating ball steering lies in its inherent mechanical advantage. Unlike rack and pinion systems, which offer a direct connection between the steering wheel and the wheels, recirculating ball systems use a worm gear and sector shaft to amplify the force applied by the driver. This means that a relatively small amount of effort on the steering wheel can translate into a much larger force at the wheels, making it easier to turn the vehicle, especially when it's heavily loaded or operating in rough terrain.

This mechanical advantage is particularly important for trucks and SUVs, which often have larger tires and heavier loads. The increased leverage provided by the recirculating ball system helps to overcome the increased resistance, making steering more manageable and less tiring for the driver. It's also crucial for off-road driving, where the wheels may encounter uneven surfaces and obstacles that require additional force to overcome. Without this mechanical advantage, steering a heavy truck in challenging conditions would be extremely difficult.

The worm gear and sector shaft design also contributes to the system's durability. By distributing the force over a larger area, it reduces the stress on individual components, extending their lifespan. This is especially important in heavy-duty applications, where the steering system is subjected to constant stress and strain. The ability to withstand these forces is a key reason why recirculating ball steering remains a popular choice for trucks and other vehicles that are built to last.

Recommendation: When is Recirculating Ball Steering Right?

Recirculating ball steering is the right choice when you need a steering system that can handle heavy loads, rough terrain, and demanding conditions. If you own a truck or SUV that you regularly use for towing, hauling, or off-road adventures, a recirculating ball system is likely the best option. Its strength, durability, and mechanical advantage make it well-suited for these applications.

However, if you prioritize precision, feedback, and a sporty driving feel, rack and pinion steering may be a better choice. This type of system is commonly found in smaller cars and performance vehicles, where responsiveness and handling are paramount. But remember, rack and pinion systems may not be able to withstand the same level of stress and strain as recirculating ball systems, making them less suitable for heavy-duty applications.

Ultimately, the best steering system depends on your specific needs and driving style. Consider the type of vehicle you own, the loads you typically carry, and the conditions you frequently encounter. By carefully weighing these factors, you can choose the steering system that will provide the best balance of performance, reliability, and comfort.

Understanding Steering Ratios

Steering ratio is a critical factor to consider when evaluating a steering system. It essentially describes how many degrees you need to turn the steering wheel for the wheels of your vehicle to turn a certain degree. A higher steering ratio means you need to turn the steering wheel more to achieve the same amount of wheel movement, resulting in easier steering but less responsiveness. Conversely, a lower steering ratio provides more immediate feedback and quicker turning, but requires more effort, especially at lower speeds.

Recirculating ball steering systems often have higher steering ratios compared to rack and pinion systems. This contributes to the feeling of "vagueness" that some drivers experience, as the steering response isn't as direct. However, this higher ratio also provides greater mechanical advantage, making it easier to steer a heavy vehicle. In trucks and SUVs, this is a desirable trade-off, as the focus is on reducing driver fatigue and ensuring manageable steering under load.

When comparing steering ratios, it's important to consider the overall driving experience. A lower steering ratio might be ideal for a sports car on a racetrack, but it would be exhausting to use in a heavy truck on a long highway drive. Recirculating ball steering systems strike a balance, providing enough responsiveness for safe handling while minimizing the effort required to steer a large vehicle.

Tips for Maintaining Recirculating Ball Steering

Maintaining your recirculating ball steering system is crucial for ensuring its longevity and optimal performance. Regularly inspect the system for signs of wear or damage, such as leaks, loose components, or excessive play in the steering wheel. Pay close attention to the ball joints, tie rod ends, and the steering gearbox itself.

Proper lubrication is also essential. The recirculating ball system relies on a constant flow of lubricant to reduce friction and prevent wear. Check the fluid level regularly and top it off as needed. Use the type of fluid recommended by the manufacturer. Consider replacing the fluid periodically to remove contaminants and ensure optimal performance. Also ensure all grease fittings are properly greased.

If you notice any issues, such as difficulty steering, unusual noises, or excessive play in the steering wheel, have the system inspected by a qualified mechanic. Ignoring these problems can lead to more serious damage and potentially compromise your safety. Early detection and repair can save you time and money in the long run.

Checking for Play in the System

One of the most common issues with recirculating ball steering systems is "play" in the steering wheel, which refers to the amount of free movement before the wheels start to turn. To check for play, start the engine and let the vehicle idle. Have someone observe the wheels while you gently turn the steering wheel back and forth. If you can move the steering wheel significantly without the wheels responding, there's likely excessive play in the system.

Several factors can contribute to play in the steering system, including worn ball joints, tie rod ends, or the steering gearbox itself. Identifying the source of the play is crucial for determining the appropriate repair. A qualified mechanic can inspect the system and diagnose the problem accurately. Replacing worn components is often the most effective way to restore the steering system to its optimal condition.

Ignoring play in the steering system can lead to a loss of control and potentially dangerous driving conditions. It's important to address this issue promptly to ensure your safety and the longevity of your vehicle. Regular inspections and timely repairs are essential for maintaining a safe and reliable steering system.

Fun Facts About Recirculating Ball Steering

Did you know that recirculating ball steering was initially developed to improve the steering of heavy machinery and military vehicles? Its robust design and ability to handle heavy loads made it a natural fit for these demanding applications. The technology was later adapted for use in trucks and SUVs, where it continues to provide reliable steering performance.

Another interesting fact is that some early recirculating ball systems used a manual adjustment mechanism to compensate for wear. This allowed drivers to tighten the system and reduce play in the steering wheel, extending the life of the components. While modern systems are more sophisticated, the basic principles remain the same.

The recirculating ball system is also surprisingly efficient. The ball bearings reduce friction to a minimum, allowing for smoother and more effortless steering. This efficiency translates into improved fuel economy and reduced wear on other vehicle components. Despite its age, the recirculating ball system remains a testament to the ingenuity of early automotive engineers.

How to Convert to Rack and Pinion

While recirculating ball steering has its advantages, some truck owners may prefer the more precise and responsive feel of rack and pinion steering. Converting a truck from recirculating ball to rack and pinion is possible, but it's a complex and costly undertaking that requires significant modifications to the vehicle's chassis and suspension system.

The first step is to identify a compatible rack and pinion unit that can handle the weight and forces of the truck. You'll also need to fabricate custom mounting brackets to attach the rack and pinion to the truck's frame. The steering linkage will need to be modified to connect the rack and pinion to the wheels. Depending on the vehicle, you may also need to upgrade the power steering pump to provide sufficient hydraulic pressure.

Converting to rack and pinion steering can significantly improve the handling and driving experience of a truck, but it's not a project to be taken lightly. It requires specialized knowledge, tools, and skills. Unless you're an experienced mechanic or fabricator, it's best to leave this conversion to a professional. Be prepared to invest a significant amount of time and money to complete the project successfully.

What If Recirculating Ball Steering Fails?

If your recirculating ball steering system fails, the consequences can be serious. You may experience difficulty steering, loss of control, or even complete steering failure. A failing steering system can significantly increase the risk of accidents, especially at high speeds or in challenging conditions.

The symptoms of a failing recirculating ball system can vary depending on the nature and extent of the damage. Common signs include excessive play in the steering wheel, difficulty turning the wheel, unusual noises when steering, and leaks from the steering gearbox. If you notice any of these symptoms, have the system inspected by a qualified mechanic immediately.

Regular maintenance and timely repairs are the best ways to prevent steering system failures. By inspecting the system regularly, lubricating the components properly, and addressing any issues promptly, you can ensure the safety and reliability of your steering system.

Listicle: 5 Reasons Trucks Still Use Recirculating Ball Steering

Here's a quick rundown of why recirculating ball steering remains a popular choice for trucks:

- Strength and Durability: Recirculating ball systems are built to withstand the heavy loads and demanding conditions that trucks often encounter.

- Mechanical Advantage: The design provides greater leverage, making it easier to steer a heavy vehicle, especially when loaded.

- Reliability: These systems are known for their robustness and longevity, requiring less frequent maintenance and repairs.

- Cost-Effectiveness: In some cases, recirculating ball systems can be more affordable than rack and pinion, especially for older vehicles.

- Proven Technology: Recirculating ball steering has a long and successful history, providing reliable steering performance for decades.

These reasons highlight the enduring value of recirculating ball steering in the trucking industry.

Question and Answer Section

Here are some frequently asked questions about recirculating ball steering:

Q: Is recirculating ball steering outdated?

A: While it's an older technology, it's not necessarily outdated. It's still a viable option for trucks and SUVs due to its strength and durability.

Q: What are the advantages of recirculating ball steering?

A: The main advantages are its ability to handle heavy loads, its robustness, and its mechanical advantage, which makes steering easier.

Q: What are the disadvantages of recirculating ball steering?

A: The main disadvantages are its less precise feel compared to rack and pinion, and potential for play in the steering wheel due to wear.

Q: How can I maintain my recirculating ball steering system?

A: Regularly inspect the system for leaks and wear, lubricate the components properly, and address any issues promptly.

Conclusion of What Is Recirculating Ball Steering? Why Trucks Still Use It

Recirculating ball steering might not be the newest or most technologically advanced steering system, but its enduring presence in trucks speaks volumes about its reliability and effectiveness. Its ability to handle heavy loads, provide mechanical advantage, and withstand harsh conditions makes it a valuable choice for vehicles that need to work hard. While rack and pinion steering offers a sportier feel, recirculating ball steering remains a dependable and proven option for trucks and other heavy-duty vehicles.